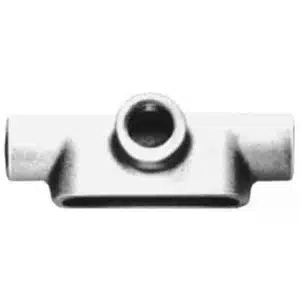

Electrical Conduit Bodies

Conduit bodies are enclosure fittings used in electrical conduit systems to provide access for pulling, splicing, or routing wires, while also allowing for changes in direction. They come in various shapes, such as LB, T, C, and L configurations, to accommodate different conduit layouts. Conduit bodies are typically made from aluminum, cast iron, or PVC, depending on the environment and application, and often have removable covers to facilitate easy maintenance or inspection of conductors. They also provide additional space for wire bending and help to simplify complex conduit runs. Shop confidently with LiveWire Supply, where fast, flexible shipping is available for every order. We carry a wide range of conduit bodies from major brands like Crouse-Hinds. For 24/7 sales assistance, call 1-650-692-0700.